Turbo Jet Waste Water

In this way, nitrification and denitrification processes can also be achieved with little effort. Additional agitators are not required. In principle, we supply equipment that is completely ready for operation and therefore ready for immediate use. The assembly on site usually only includes the fastening by means of tensioning ropes and can usually be carried out without problems by the personnel of the sewage treatment plant.

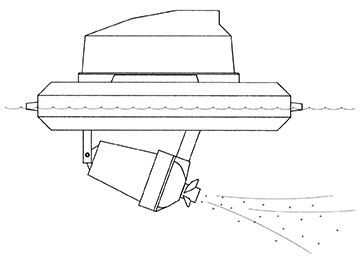

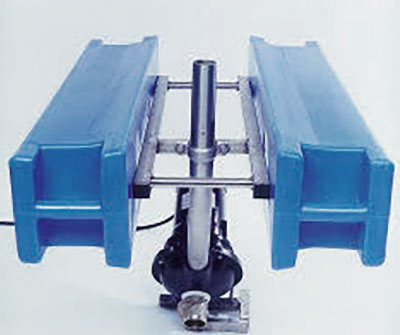

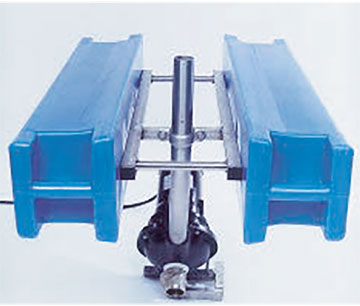

The heart of the TURBO-JET wastewater aeration system is the aeration unit. The main component is the robust submersible motor (protection class IP 68). All materials have been selected for tough use in waste water and have proven themselves over many years. The motor pot is made of grey cast iron (GG 25) and is therefore robust and durable. Motor shaft, brackets and screw connections are made of stainless steel. The engine is sealed with a mechanical seal in an oil bath (vegetable engine oil).

The vacuum chamber is also made of grey cast iron. The propeller has been specially developed by us for „dirty water“ applications. The material used is a particularly hard bronze alloy (tungsten carbide bronze). This ensures long operating times. Wear and tear on the propeller is hardly noticeable even after several years of operation. The propeller shape was developed in such a way that no blockages or deposits are possible. The free passage in the propeller core ensures the addition of air. The dimensioning ensures trouble-free continuous operation.

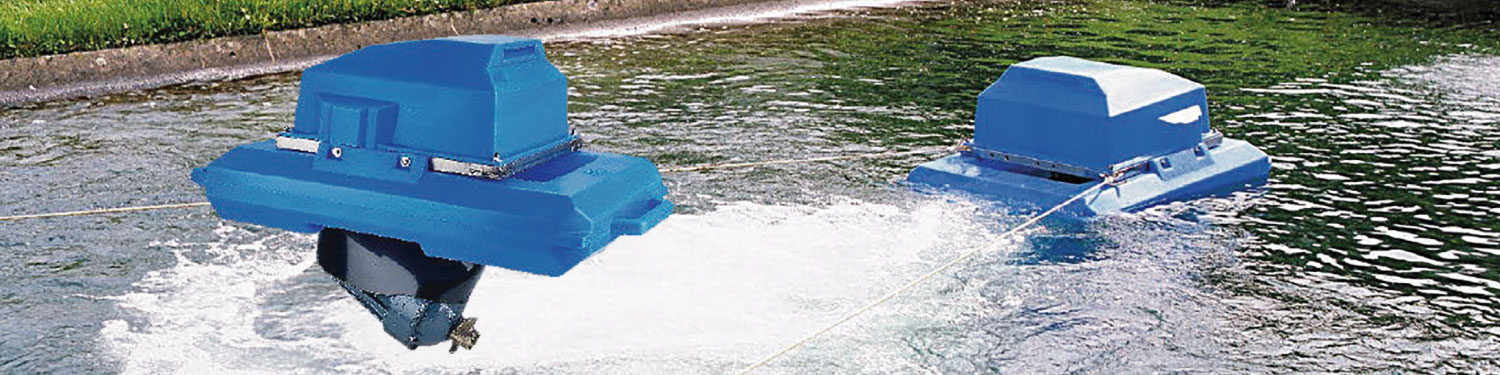

TURBO-JET floating can be optimally used for expansion or retrofitting – but also for original equipment. The floating unit only has to be placed on the waste water, pulled to the desired position with the aid of stainless steel wire ropes and attached to the edge.

Then all you need is a connection to the power supply! It couldn‘t be simpler – or faster or cheaper. Consider the cost savings by omitting the installation (electricity connection excluded).

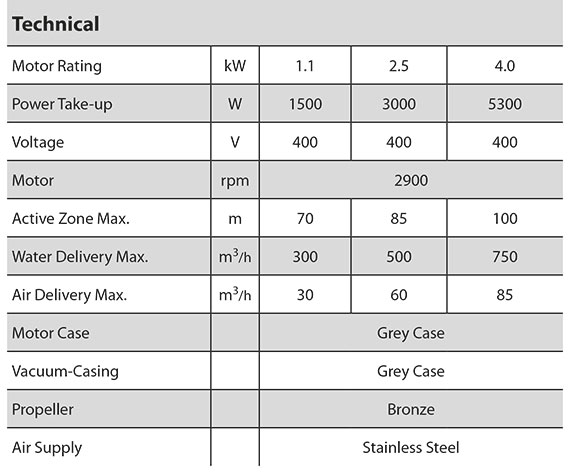

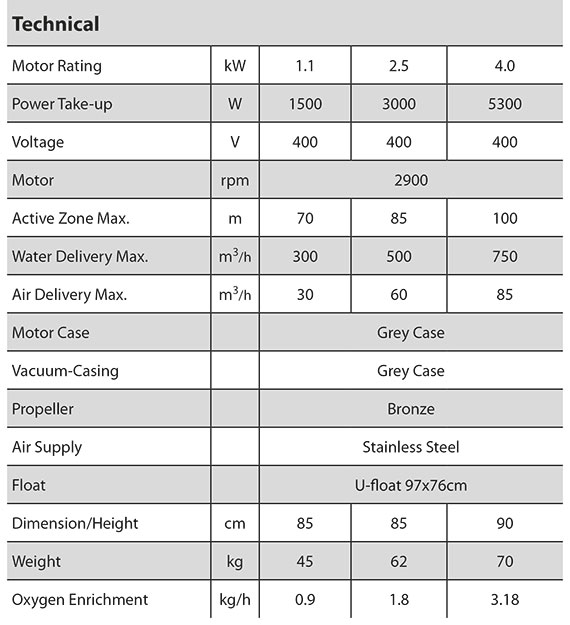

Technical Specifications

Advantages

- flexible and versatile

- minimum energy consumption

- good oxygen input

- large circulation

- low acquisition costs – fast amortisation

- low maintenance costs

- no installation

- no laying of air ducts

- no construction work

- absolutely winterproof

- immediately usable

- almost noiseless

TURBO-JET in floating design is particularly suitable for pools with fluctuating water levels, as the propeller immersion depth of floating units is always constant and therefore always optimal, while permanently installed units have problems here.

TURBO-JET in floating design is particularly suitable for pools with fluctuating water levels, as the propeller immersion depth of floating units is always constant and therefore always optimal, while permanently installed units have problems here. For use in closed basins or for attachment to existing bridges of failed aeration rollers, we manufacture the aeration unit with a stainless steel bracket. This version can also be used for retrofitting or original equipment. Here again we deliver a completely assembled unit ready for operation.

For use in closed basins or for attachment to existing bridges of failed aeration rollers, we manufacture the aeration unit with a stainless steel bracket. This version can also be used for retrofitting or original equipment. Here again we deliver a completely assembled unit ready for operation.