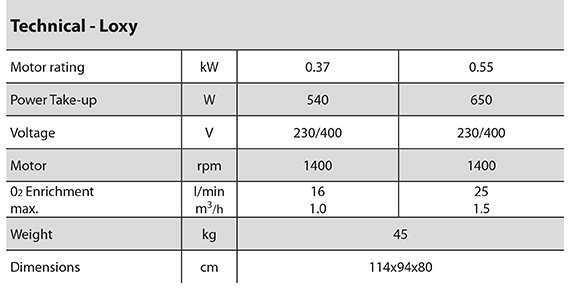

LOXY®

With the help of this new invention, LOXY® achieves a very good level of oxygen enrichment with low energy consumption. Previous systems worked with ‘bottlenecks’ (for example, the venturi nozzle – disadvantage: a relatively high water pressure is required) or with wheels or brush wheels (disadvantage: a lot of energy is required to move the water) Compared to these systems, LOXY® has the advantage that, due to the rotary mixer, only a very small portion of the water needs to be accelerated; no water pressure is required.

A fluidised bed that lowers energy consumption and leads to excellent oxygen enrichment is created on the surface of the novel rotary mixer. The main plastic body of LOXY® is shaped such that water is sucked up from below and exits through an opening on the side. Therefore, short-circuiting cannot occur. The main body is enclosed by two floats. All of the plastic parts are made of polyethylene and are extremely robust.

This elegantly simple LINN development does away with submersible motors, belt drives and external bearing blocks. LOXY® uses a durable, energy-saving electric motor (according to the latest IE3 standard) with a stainless steel shaft on which the rotary mixer is directly mounted. The drive is thus completely maintenance-free! The electric motor is located in a protective housing on the body base and can be removed easily and quickly. LOXY® does not need any screens to protect the fish or exclude leaves, so clogging within the system is impossible!

LOXY® is supplied assembled, ready for use and with a 20 m cable and a motor protection plug.

Technical Specifications

Advantages

- Low energy consumption – very efficient

- Pioneering technology

- Safe operation

- Maintenance-free

- Lightweight and compact

- Clog-free

- Great value for the money

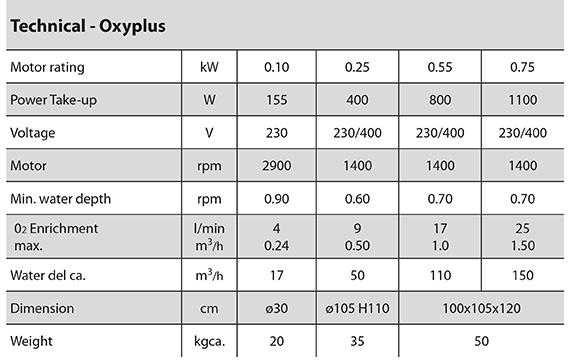

Oxyplus works with a comparatively low pressure difference (max. 0.1 bar). Oxygen-poor water is drawn in and mixed intensively with the pure oxygen which has been introduced. An increase in the surface area of the medium is obtained by mixing and oxygen is taken up. By this means, other gases (e. g. Nitrogen) will also be driven out. These gases escape through the ventilation pipe of the apparatus with a minimal amount of oxygen.

Oxyplus works with a comparatively low pressure difference (max. 0.1 bar). Oxygen-poor water is drawn in and mixed intensively with the pure oxygen which has been introduced. An increase in the surface area of the medium is obtained by mixing and oxygen is taken up. By this means, other gases (e. g. Nitrogen) will also be driven out. These gases escape through the ventilation pipe of the apparatus with a minimal amount of oxygen.

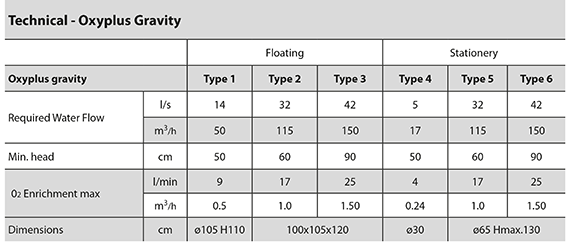

Our Oxyplus oxygen transfer system works with very low pressure difference. This makes the use of this system possible, without a separate pump, where specific requirements are fulfilled.

Our Oxyplus oxygen transfer system works with very low pressure difference. This makes the use of this system possible, without a separate pump, where specific requirements are fulfilled.

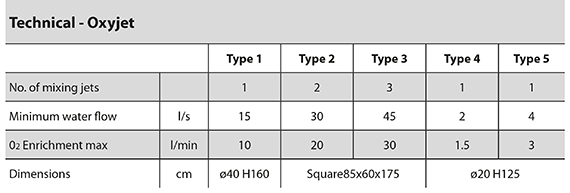

Oxyjet is an open oxygen input system which is put directly into the pond or channel. The system is ideal for use in recirculation complexes where the water must be circulated anyway. Then Oxyjet circulates the water and enriches it with oxygen at the same time. Oxyjet can be used wherever there is a hydraulic pressure head of at least 60cm. The outstanding performance of Oxyjet is due to patented special jets. Compared to conventional jets, a very high gas transfer is achieved. The jets result in a very high bubble detention time in the mixing chamber, and therefore a very high effectiveness and efficiency.

Oxyjet is an open oxygen input system which is put directly into the pond or channel. The system is ideal for use in recirculation complexes where the water must be circulated anyway. Then Oxyjet circulates the water and enriches it with oxygen at the same time. Oxyjet can be used wherever there is a hydraulic pressure head of at least 60cm. The outstanding performance of Oxyjet is due to patented special jets. Compared to conventional jets, a very high gas transfer is achieved. The jets result in a very high bubble detention time in the mixing chamber, and therefore a very high effectiveness and efficiency.